TYCOON GROUP(ASIA).,LTD: Desalination methods

Desalination is the production of fresh water by desalination of seawater. [1] It is an open-source incremental technology for realizing water resource utilization. It can increase the total amount of fresh water and is not affected by time, space and climate. It can ensure a stable water supply for coastal residents’ drinking water and industrial boiler water replenishment.

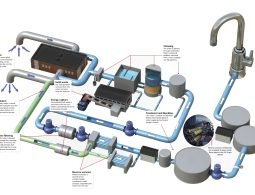

The process of obtaining fresh water from seawater is called desalination. The desalination methods used include seawater freezing, electrodialysis, distillation, reverse osmosis, and ammonium carbonate ion exchange. The application of reverse osmosis membrane and distillation is the mainstream in the market. [2]

More than 100 scientific research institutions in more than a dozen countries in the world are conducting research on desalination, and there are hundreds of desalination facilities with different structures and capacities in operation. A modern large-scale desalination plant can produce thousands, tens of thousands or even nearly one million tons of fresh water every day. The cost of water is constantly decreasing. In some countries, it has been reduced to a price similar to that of tap water. The amount of desalinated water in some areas has reached the scale of national and urban water supply.

The main purpose is to use seawater desalination to produce fresh water. [3] It is an open-source incremental technology for realizing water resource utilization. It can increase the total amount of fresh water and is not affected by time, space and climate. The water quality is good and the price is becoming more reasonable. It can ensure a stable water supply for coastal residents to drink water and industrial boiler water replenishment. The process of obtaining fresh water from seawater is called seawater desalination. [4]

Seawater desalination is mainly used to provide drinking water and agricultural water. Sometimes edible salt is also produced as a by-product. Seawater desalination is very popular in the Middle East and is also used on some islands and ships.

The cumulative seawater desalination capacity of projects that have been built and are about to be built in my country is about 600,000 tons/day. From the perspective of policy planning, the industry market capacity has more than 5 times the growth space in the next ten years, and the prospects are relatively optimistic. The cost of desalinating seawater has dropped to 4-5 yuan/ton, and the economic feasibility has been greatly improved. Considering the cost reduction brought about by future technological progress and policy support, the seawater desalination industry is expected to experience explosive growth in the future.

Historically, seawater desalination has been a dream that humans have pursued for hundreds of years. In ancient times, there were stories and legends about removing salt from seawater. The large-scale application of seawater desalination technology began in the arid Middle East, but it is not limited to this region. Since more than 70% of the world’s population lives within 120 kilometers of the ocean, seawater desalination technology has been rapidly applied in many countries and regions outside the Middle East in the past 20 years. The latest data shows.

Common methods

There are more than 20 seawater desalination technologies in the world, including reverse osmosis, low multi-effect, multi-stage flash evaporation, electrodialysis, steam distillation, dew point evaporation, hydropower cogeneration, thermal membrane cogeneration, and seawater desalination technology using nuclear energy, solar energy, wind energy, tidal energy, etc., as well as multiple pre-treatment and post-treatment processes such as microfiltration, ultrafiltration, and nanofiltration.

From a broad classification point of view, it is mainly divided into two categories: distillation (thermal method) and membrane method, among which low multi-effect distillation, multi-stage flash evaporation and reverse osmosis membrane method are the mainstream technologies in the world. Generally speaking, low multi-effect has the advantages of energy saving, low seawater pretreatment requirements, and high desalinated water quality; reverse osmosis membrane method has the advantages of low investment and low energy consumption, but high seawater pretreatment requirements; multi-stage flash evaporation method has the advantages of mature technology, reliable operation, and large device output, but high energy consumption. It is generally believed that low multi-effect distillation and reverse osmosis membrane method are the future direction. It is estimated that during the 12th Five-Year Plan period, my country’s seawater desalination will reach 1.5 million to 2 million tons per day, which is three or four times the current production capacity, and the investment scale will reach about 20 billion yuan.

Principle of frozen seawater desalination method: The triple point of seawater is a special point where the three phases of seawater vapor, liquid and solid coexist and reach equilibrium. If the pressure or temperature deviates from the triple point, the balance is destroyed, and the three phases will automatically tend to one or two phases. Vacuum freezing seawater desalination is a low-cost desalination method that utilizes the triple point principle of seawater, uses water itself as a refrigerant, evaporates and freezes seawater at the same time, and then separates and washes the ice crystals to obtain desalinated water. Compared with distillation and membrane desalination, frozen seawater desalination has low energy consumption, light corrosion and scaling, simple pretreatment, small equipment investment, and can handle seawater with high salt content. It is an ideal seawater desalination method.

Freezing method

Freezing method, that is, freezing seawater to freeze it, and the salt is separated while the liquid seawater becomes solid ice. Both the freezing method and the distillation method have drawbacks that are difficult to overcome. The distillation method consumes a lot of energy and produces a lot of scale in the instrument, but the fresh water obtained is not much; the freezing method also consumes a lot of energy, but the fresh water obtained tastes bad and is difficult to use.

Precooling of the frozen seawater desalination process After degassing, the seawater can exchange heat with the concentrated brine and desalinated water discharged from the evaporation crystallizer, and precool to near the freezing point of the seawater. Degassing of the frozen seawater desalination process Because the non-condensable gases dissolved in the seawater will be almost completely released under low pressure conditions, and will not condense in the condenser. This will increase the pressure of the system, making the pressure in the evaporation crystallizer higher than the two-phase point pressure, destroying the operation. Obviously, the decompression degassing method is suitable for this system.

Distillation method

Desalination is the main factor affecting the evaporation and freezing rate of seawater.

Ice-salt water in the seawater desalination process is a solid-liquid system. Ordinary separation methods can separate ice-salt water, but different separation methods will result in different salt contents of ice crystals. The experimental results show that the salt content of ice crystals obtained by the vacuum filtration method is much lower than that of ice crystals obtained by the normal pressure filtration method.

Steam condensation in the desalination process In the evaporation crystallizer, in addition to the precipitation of ice crystals from seawater, a large amount of steam will also be produced. This steam must be removed in time to allow the seawater to evaporate and freeze continuously.

Reverse osmosis

Commonly known as ultrafiltration, it is a membrane separation desalination method that was only adopted in 1953. [6] This method uses a semipermeable membrane that only allows solvents to pass through but not solutes to pass through to separate seawater from fresh water. Under normal circumstances, fresh water diffuses through the semipermeable membrane to the seawater side, thereby gradually raising the liquid level on the seawater side until it stops at a certain height. This process is called osmosis. At this time, the static pressure of the water column on the seawater side is called osmotic pressure.

If an external pressure greater than the osmotic pressure of seawater is applied to the seawater side, the pure water in the seawater will reverse osmosis into the freshwater. The biggest advantage of reverse osmosis is energy saving. Its energy consumption is only 1/2 of that of electrodialysis and 1/40 of that of distillation. Therefore, since 1974, developed countries such as the United States and Japan have successively shifted their development focus to reverse osmosis.

Reverse osmosis desalination technology has developed rapidly, and the project cost and operating cost have continued to decrease. The main development trends are to reduce the operating pressure of the reverse osmosis membrane, improve the recovery rate of the reverse osmosis system, cheap and efficient pretreatment technology, and enhance the system’s anti-pollution ability.

Solar energy method

In the early days, humans used solar energy for seawater desalination, mainly using solar energy for distillation, so early solar seawater desalination devices were generally called solar distiller. Distillation system An example of a passive solar distillation system is a disc solar distiller, which has been used for nearly 150 years. Because of its simple structure and convenient material acquisition, it is still widely used.

Research on disc solar distiller mainly focuses on the selection of materials, the improvement of various thermal properties, and its use in conjunction with various solar collectors. Compared with traditional power sources and heat sources, solar energy has the advantages of safety and environmental protection. Combining the two systems of solar energy collection and desalination process is a sustainable desalination technology.

Solar desalination technology has gradually attracted people’s attention due to its advantages such as not consuming conventional energy, no pollution, and high purity of fresh water. [7] Solar distillation is a simple solar distiller. The distiller consists of a water tank with a black porous felt core floating hole in the water tank, and a transparent, edge-sealed glass cover on the top of the tank. Sunlight passes through the transparent cover and projects onto the black insulated bottom of the tank, converting it into heat energy. Therefore, the water surface temperature in the plastic core is always higher than the temperature at the bottom of the transparent cover. Water evaporates from the felt core, and the steam diffuses onto the cover to cool into liquid and is discharged into the opaque distillation tank.

Low-temperature distillation

Low-temperature multi-effect distillation desalination technology

Low-temperature multi-effect seawater desalination technology refers to a distillation desalination technology with a maximum evaporation temperature of brine below 70°C. It is characterized by connecting a series of horizontal tube spray falling film evaporators in series, inputting a certain amount of steam into the first effect, and the evaporation temperature of the subsequent effect is lower than that of the previous effect. Then, through multiple evaporations and condensations, a desalination process of distilled water with a volume of steam multiple times is obtained.

Multi-effect evaporation is to evaporate the heated seawater in multiple evaporators connected in series. The steam evaporated from the previous evaporator is used as the heat source of the next evaporator and condensed into fresh water. Among them, low-temperature multi-effect distillation is one of the most energy-saving methods in distillation. Due to the factor of energy saving, low-temperature multi-effect distillation technology has developed rapidly, the scale of the device has been expanding, and the cost has been decreasing. The main development trend is to increase the first effect temperature and the water production capacity of the device; use cheap materials to reduce the project cost, increase the operating temperature, and improve the heat transfer efficiency. A low-temperature multi-effect distillation method for seawater desalination equipment includes a steam supply system, a water distribution system, an evaporator, a fresh water tank and a concentrated water tank. The raw steam inlet of the steam supply system is placed on the intermediate effect evaporator. The working method is as follows: (1) the water distribution system sprays seawater; (2) raw steam is input into the evaporation tube of the intermediate effect evaporator; (3) the steam condenses in the evaporation tube and transfers heat, and absorbs heat outside the evaporation tube to produce evaporation; (4) the new steam is transported to the evaporation tubes on both sides. The outside of the tube absorbs heat and produces evaporation; (6) each effect evaporator repeats the evaporation and condensation process; (7) distilled water enters the fresh water tank; (8) concentrated brine enters the concentrated water tank.

Multi-stage flash evaporation

Flash evaporation refers to the phenomenon that part of the seawater at a certain temperature evaporates rapidly under the condition of a sudden decrease in pressure. Multi-stage flash evaporation seawater desalination is to evaporate the heated seawater in multiple flash chambers with gradually decreasing pressure in turn, and condense the steam to obtain fresh water. The global seawater desalination device still has the largest output and the most mature technology. It has high operating safety and flexibility. It is mainly built in conjunction with thermal power plants. It is suitable for large and super-large desalination devices and is mainly used in Gulf countries. Multi-stage flash evaporation technology is mature and reliable in operation. The main development trend is to improve the water production capacity of a single device, reduce unit power consumption, and improve heat transfer efficiency.

Electrodialysis

The technical key of this method is the development of a new ion exchange membrane. Ion exchange membrane is a functional membrane with a thickness of 0.5-1.0mm, which is divided into positive ion exchange membrane (cation membrane) and negative ion exchange membrane (anion membrane) according to its selective permeability. Electrodialysis is to alternately arrange the cation membrane and anion membrane with selective permeability to form multiple independent compartments where seawater is desalinated, while the adjacent compartments are concentrated, and fresh water and concentrated water are separated. Electrodialysis can not only desalinate seawater, but also be used as a means of water treatment to contribute to the reuse of sewage. In addition, this method is also increasingly used in the concentration, separation and purification of chemical, pharmaceutical, food and other industries.

Compressed steam distillation

The distillation method is a method of boiling and vaporizing seawater by heating it, and then condensing the steam into fresh water. The distillation desalination technology is the earliest desalination technology put into industrial application. It is characterized by its applicability even in seawater environments with severe pollution and high biological activity, and its high water purity. Compared with membrane desalination technology, the distillation method has the advantages of being able to utilize low-grade heat from power plants and other factories, having low requirements for the quality of raw seawater, and having large production capacity of the device. It is one of the mainstream technologies for seawater desalination at present.

Dew point evaporation

Dew point evaporation desalination technology is a new method for desalination of brackish water and seawater. It is based on the principle of carrier gas humidification and dehumidification, while recovering the heat of condensation and dehumidification, and the heat transfer efficiency is controlled by the heat transfer on the mixed gas side. Dew point evaporation desalination technology uses air as a carrier, and produces fresh water by humidifying and dehumidifying it with seawater or brackish water, and couples the dehumidification process with the humidification process through heat transfer, so that the condensation latent heat is directly transferred to the evaporation chamber, providing vaporization latent heat for evaporating salt water, so as to improve the thermal efficiency of the process. Two humidification/dehumidification coupled dew point evaporation desalination equipment with effective heat transfer areas of 9.6 m2 and 2.75 m2 respectively were established. The corresponding experimental equipment and computer data acquisition system were established. The basic process and parameter correlation experiment of dew point evaporation desalination and the enhanced heat transfer/mass transfer desalination experiment were successfully completed.

Vacuum freezing

The vacuum freezing seawater desalination process includes degassing, precooling, evaporation crystallization, ice crystal washing, steam condensation and other steps. The seawater desalination product can meet the national drinking water standard, which is an ideal seawater desalination method.

“I try as much as possible to give you a great basic product and what comes out, I feel, is really amazing.”

Kathryn Murphy

Founder

New adsorption method

Non-pressurized osmotic adsorption

Non-pressurized osmotic desalination, or “forward osmosis”, allows water to pass through a porous membrane into a solution or solid with a super absorbent. The salt concentration is even higher than that of seawater, but the special salt in the solution evaporates easily. It is divided into solid salt and liquid salt directions. Solid salt desorption consumes less energy.

The other two methods have innovations and improvements in film structure

Carbon nanotube film is a film with small holes made of carbon nanotubes, and another film for permeation.

Protein membrane is a film with pores made of proteins that guide water molecules through the cell membrane of living cells.