- CONSTRUCTION MACHINERY

- DIESEL ENGINE BRAND

- DIESEL ENGINE DISPLACE TYPE

- DIESEL ENGINE USAGE TYPE

- DYNAMOTOR APPLICATION SCENARIOS

- ENGINE ENERGY TYPE

- FREIGHT VEHICLES

- GENERATOR POWER TYPE

- MINING MACHINE

- ACCESSORIES

- BELT CONVEYOR

- BOX CRUSHER

- CIRCLE LIBRATING SCREEN

- CONE CRUSHER

- DOU CHAIN

- DOU TYPE HOIST

- DREDGER/GOLD BOAT

- DRUN SIEVE

- ELECTRO MAGNET HIGH FREQUENCY SCREEN

- Mine bucket

- MOBILE CRUSHING STATION

- ROADHEADER

- ROLLS CRUSHER

- SCREW CONVEYOR

- SHAVING BED

- STONE SCRUBBER

- TRANSFER PUMP

- VIBRATING FEEDER

- WASHING SAND MACHINE

- NATURAL GAS HEAT SOURCE

- PASSENGER VEHICLES

- WATER TREATMENT

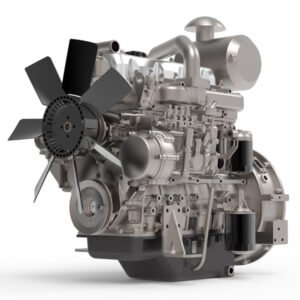

WP12 series marine diesel engines (258-405kW)

High-speed engine products including WP4.1,WP4,WP6,WP7,WD10,WD12,WP10, WP12,WP13,M26,M33, which are mainly used as the main engine and auxiliary engine of the high-speed ships and boats, passenger ship, and fishing boat and inland river transport ship; WHM6160/170 medium speed engine products, which are mainly used as the main engine, electric propeller and auxiliary engine of the bulk cargo carrier, car/passenger ferry, public service ship, offshore support vessel, ocean fishing vessel, engineering ship, multi-purpose ship; CW200/CW250/WH620/WH20/WH25/WH28 medium speed engine products, which are mainly used as the main engine, and auxiliary engine of the engineering ship, passenger ship, fishing boat, and bulk cargo carrier; and MAN series L21/31, L23/30A, L27/38, L32/40 and V32/40 products, which are mainly used as the main engine, electric propeller and auxiliary engine of the bulk cargo carrier, engineering ship, multi-purpose ship, and marine traffic management ship.

Product Parameters

| Type | Four-stroke, water-cooled, in-line, supercharged and intercooled | Number of cylinders | 6 |

| Bore/stroke | 126×155(mm) | Displacement | 11.59L |

| Startup method | Electric start | Oil consumption rate | ≤0.5g/kW·h |

| noise | ≤100dB(A) | Idle | 600±50(r/min |

| Crankshaft rotation direction (facing the flywheel end) |

Counterclockwise | / | / |

| Length × Width × Height / Net Weight | Mechanical pump

Electronically controlled pump, mid-mounted supercharger Electronically controlled pump, post-supercharger |

1695×858×1385(mm)

1695×818×1385(mm) 1683×928×1264(mm) |

1200kg

1200kg 1200kg |

Note: Product parameters and models are for reference only. Please contact relevant personnel to obtain official information on delivery time and fishing vessel models.

Product spectrum

| series | model | Air intake method | Rated power kW/Ps |

Rated speed r/min | Oil supply method | Emission levels | Power classification |

| WP12 | WP12C350-15 | Supercharged intercooler | 258/350 | 1500 | Mechanical pump | IMOⅡ/China I | P1 |

| WP12C400-18 | Supercharged intercooler | 295/400 | 1800 | Mechanical pump | IMOⅡ/China I | P1 | |

| WP12C450-21 | Supercharged intercooler | 330/450 | 2100 | Mechanical pump | IMOⅡ/China I | P1 | |

| WP12C350-15E121 | Supercharged intercooler | 258/350 | 1500 | Electronically controlled common rail | IMOⅡ/China I | P1 | |

| WP12C400-18E121 | Supercharged intercooler | 295/400 | 1800 | Electronically controlled common rail | IMOⅡ/China I | P1 | |

| WP12C450-21E121 | Supercharged intercooler | 330/450 | 2100 | Electronically controlled common rail | IMOⅡ/China I | P1 | |

| WP12C500-21E121 | Supercharged intercooler | 368/500 | 2100 | Electronically controlled common rail | IMOⅡ/China I | P2 | |

| WP12C550-21E121 | Supercharged intercooler | 405/550 | 2100 | Electronically controlled common rail | IMOⅡ/China I | P3 |

Note: Product parameters and models are for reference only. Please contact relevant personnel to obtain official information on delivery time and fishing vessel models.

WP12 Series Marine Diesel Engine

- Torque reserve 25%-35%

- Minimum fuel consumption 191g/kW·h

- Overhaul period 20000h

- Emissions meet IMO II/China I

Product Advantages

Safe and reliable

- High-strength design of engine body, piston, bearing and other structural parts ensures the reliability of diesel engine under high explosion pressure

- Utilizing Weichai’s global excellent supplier system, the quality of parts is reliable

- Withstand rigorous durability tests to ensure the reliability of key components, and the overhaul period of the whole machine is more than 20,000 hours

- Complete self-diagnosis system, complete failure protection mode, safe control strategy

Powerful

- Precise control of the electronic control unit, high injection pressure, small speed fluctuation, strong power

- Low-speed high-torque design, torque reserve 25%-35%, quick response, fast speed-up

Economical and fuel-efficient

- Optimize the injection pattern, accurately control the injection pressure, injection amount and injection time, fully atomize the fuel, and achieve the lowest fuel consumption rate of 191g/kW·h

Comfortable and environmentally friendly

- It can realize multiple injections such as pre-injection and post-injection, and the noise and vibration are reduced by 20% compared with the mechanical pump system.

- Water-jacketed exhaust pipe and water-jacketed exhaust tail pipe to reduce cabin temperature

- Emissions meet IMO TierⅡ and China Phase I regulations

Strong practicality

- Optional configurations include LCD Internet instrument, vibration isolation pad, hand pressure oil pump, etc. to meet different customer needs

- Horizontal air filter and rear-mounted supercharger reduce the height of the whole machine and facilitate the layout of the cabin

- Adjust different control strategies according to different performance requirements

- Receive/output a variety of control signals to meet automation control requirements

Buy 1 Get 1 Free

Unbetable Quality

Recent Products

Mining, transportation, processing

Construction Assistant

Recent Products

You may add any content here from XStore Control Panel->Sales booster->Request a quote->Ask a question notification

At sem a enim eu vulputate nullam convallis Iaculis vitae odio faucibus adipiscing urna.

Reviews

There are no reviews yet.