No reminder after sale, please ask for the latest,what`up app:+86 137 0536 8461

Shopping cart (0)

Subtotal: $0.00

Spend $350.00 to get free shipping

Congratulations! You've got free shipping.

Menu

Categories

- CONSTRUCTION MACHINERY

- DIESEL ENGINE BRAND

- DIESEL ENGINE DISPLACE TYPE

- DIESEL ENGINE USAGE TYPE

- DYNAMOTOR APPLICATION SCENARIOS

- ENGINE ENERGY TYPE

- FREIGHT VEHICLES

- GENERATOR POWER TYPE

- MINING MACHINE

- ACCESSORIES

- BELT CONVEYOR

- BOX CRUSHER

- CIRCLE LIBRATING SCREEN

- CONE CRUSHER

- DOU CHAIN

- DOU TYPE HOIST

- DREDGER/GOLD BOAT

- DRUN SIEVE

- ELECTRO MAGNET HIGH FREQUENCY SCREEN

- Mine bucket

- MOBILE CRUSHING STATION

- ROADHEADER

- ROLLS CRUSHER

- SCREW CONVEYOR

- SHAVING BED

- STONE SCRUBBER

- TRANSFER PUMP

- VIBRATING FEEDER

- WASHING SAND MACHINE

- NATURAL GAS HEAT SOURCE

- PASSENGER VEHICLES

- WATER TREATMENT

K Series Marine Engine

SKU:

Brand:

Return:

none

Description

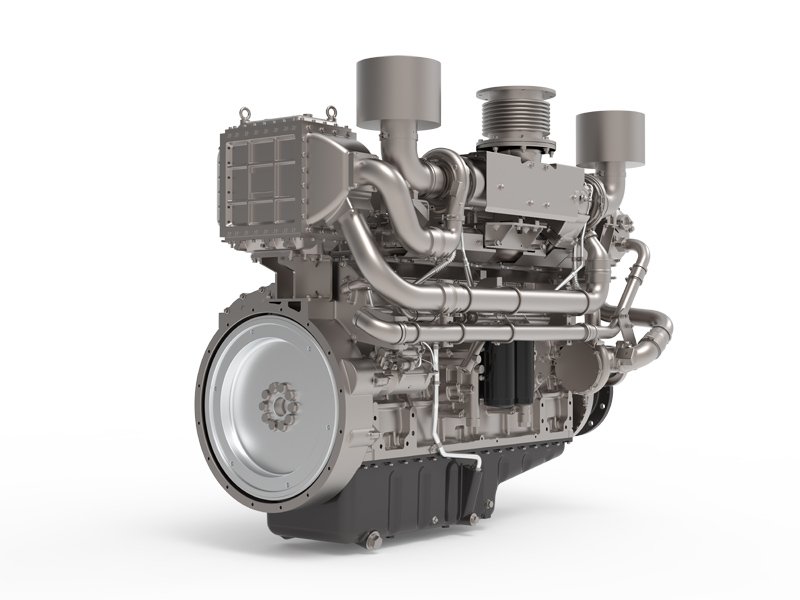

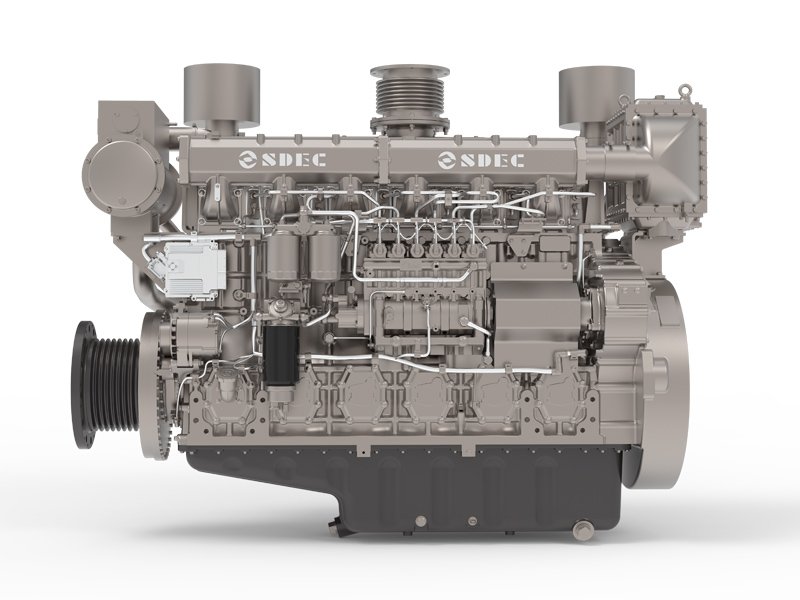

The K series engine is a medium to high speed marine diesel engine developed by SDEC, relying on many years of experience in marine engine design and development, and absorbing excellent and mature technologies from both home and abroad. The marine engine can adapt to various working conditions, and features superior performance compared with similar engines in the industry. It’s characterized by compact structure, high reliability, low noise, improved fuel efficiency, aesthetic appearance, and is applicable to various inland cargo ships, fishing boats, engineering ships, transportation ships, 300-600kW marine generator sets, etc.

Request a Quote

🔥 7 items sold in last 3 hours

41 people are viewing this product right now

Your Payment is 100% Secure

- Manufactured according to high standards, advanced and reliable

The K series was developed strictly according to SAIC’s GPDP standard process. With an integrated engine design, the marine engine comes with high-strength body and cylinder head, and forged steel crankshaft, and core components which are all supplied by well-known brands. It has an average engine overhaul period of over 20000 hours. - Strong power and high fuel efficiency

Designed with four valves, dual turbocharged structure, fully efficient air intake, and dual electronic control unit, etc., the marine engine are available with two types including high power engine with electronically controlled high pressure common rail, and low power engine with electronically controlled pump. With wide power and torque range, the engine is applicable to various working conditions with medium and heavy load requiring high torque. The minimum fuel consumption reaches 190g/kW•h, which saves more than 10% fuel than similar products in the market. - Strong adaptability and various configuration

Users choose different models according to different working conditions, among which 33W marine engine is suitable for high speed working conditions, and 38W is suitable for medium to low speed working conditions. Engine starting method, output interface, seawater pump with different flow rates, anti-corrosion cooling system, pre supply oil pump and other configurations are optional. - Comfortable and environmentally friendly, superior NVH (Noise, Vibration and Harshness)

The engine has a compact structure and attractive appearance. The NVH optimization design of the engine effectively reduces vibration and noise, improving the comfort of crew and passengers. - Long interval maintenance in a convenient manner

Due to modular design, extremely few faults will occur. The marine engine is designed with one cylinder and one head, making operation and maintenance more convenient.

| Type | In-Line Type, Water-Cooled, 4-Stroke, Wet Cylinder Liners |

| Bore/Stroke | 170x185mm |

| Min. Fuel Consumption | 185g/kW.h |

| Starting Method | Air Start, Electric Start, Air/Electric Start |

| Firing Sequence | 1-5-3-6-2-4 |

| Noise | ≤115dB(A) |

| Crankshaft Rotation Direction (facing the flywheel) | Counterclockwise |

| Cylinder No. | 6 |

| Displacement | 25.2L |

| Oil Consumption | 0.5g/kW.h |

| Certificate | CCS/IMOⅡ |

| Flywheel and Flywheel Housing | SAE0#&18# |

| Engine Overhaul Period | 20000h |

| Dimensions (LxWxH) | 2108x1088x165mm |

| Net Weight | 2850kg |

| Model | Type | Displacement (L) | Rated Power(kW) | Rated Power(HP) | Speed(rpm) | Aspiration | Fuel Control System | Output Interface | Weight (kg) | Certificate | Emission |

| SC25K880.18CA21 | 6 Cylinders / In-Line | 25.2 | 637 | 866 | 1800 | TA | ECU+CR | SAE 0#/18′ | 2850 | CCS | IMO TIER II |

| SC25K800.18CA1 | 6 Cylinders / In-Line | 25.2 | 576 | 783 | 1800 | TA | EUP | CCS | IMO TIER II | ||

| SC25K760.18CA1 | 6 Cylinders / In-Line | 25.2 | 545 | 741 | 1800 | TA | EUP | CCS | IMO TIER II | ||

| SC25K700.18CA1 | 6 Cylinders / In-Line | 25.2 | 505 | 686 | 1800 | TA | EUP | CCS | IMO TIER II | ||

| SC25K650.18CA1 | 6 Cylinders / In-Line | 25.2 | 468 | 636 | 1800 | TA | EUP | CCS | IMO TIER II | ||

| SC25K600.18CA1 | 6 Cylinders / In-Line | 25.2 | 432 | 588 | 1800 | TA | EUP | CCS | IMO TIER II | ||

| SC25K800.15CA1 | 6 Cylinders / In-Line | 25.2 | 576 | 783 | 1500 | TA | EUP | CCS | IMO TIER II | ||

| SC25K760.15CA1 | 6 Cylinders / In-Line | 25.2 | 545 | 741 | 1500 | TA | EUP | CCS | IMO TIER II | ||

| SC25K665.15CA1 | 6 Cylinders / In-Line | 25.2 | 480 | 652 | 1500 | TA | EUP | CCS | IMO TIER II | ||

| SC25K620.15CA1 | 6 Cylinders / In-Line | 25.2 | 447 | 608 | 1500 | TA | EUP | CCS | IMO TIER II | ||

| SC25K670.13CA1 | 6 Cylinders / In-Line | 25.2 | 480 | 652 | 1350 | TA | EUP | CCS | IMO TIER II | ||

| SC25K580.13CA1 | 6 Cylinders / In-Line | 25.2 | 417 | 567 | 1350 | TA | EUP | CCS | IMO TIER II |

Be the first to review “K Series Marine Engine” 取消回复

Buy 1 Get 1 Free

Unbetable Quality

Shop Now

Recent Products

Efficient and fast delivery

Secure Payments

100% Full logistics tracking

Comprehensive technical support

Mining, transportation, processing

Construction Assistant

Go to browse

Recent Products

You may add any content here from XStore Control Panel->Sales booster->Request a quote->Ask a question notification

At sem a enim eu vulputate nullam convallis Iaculis vitae odio faucibus adipiscing urna.

Reviews

There are no reviews yet.