- CONSTRUCTION MACHINERY

- DIESEL ENGINE BRAND

- DIESEL ENGINE DISPLACE TYPE

- DIESEL ENGINE USAGE TYPE

- DYNAMOTOR APPLICATION SCENARIOS

- ENGINE ENERGY TYPE

- FREIGHT VEHICLES

- GENERATOR POWER TYPE

- MINING MACHINE

- ACCESSORIES

- BELT CONVEYOR

- BOX CRUSHER

- CIRCLE LIBRATING SCREEN

- CONE CRUSHER

- DOU CHAIN

- DOU TYPE HOIST

- DREDGER/GOLD BOAT

- DRUN SIEVE

- ELECTRO MAGNET HIGH FREQUENCY SCREEN

- Mine bucket

- MOBILE CRUSHING STATION

- ROADHEADER

- ROLLS CRUSHER

- SCREW CONVEYOR

- SHAVING BED

- STONE SCRUBBER

- TRANSFER PUMP

- VIBRATING FEEDER

- WASHING SAND MACHINE

- NATURAL GAS HEAT SOURCE

- PASSENGER VEHICLES

- WATER TREATMENT

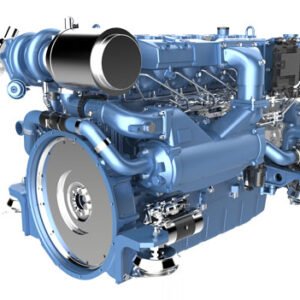

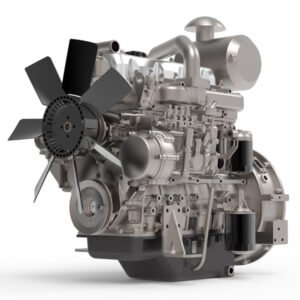

E Series Engine for Agricultural Equipment

The E series engine features excellent reliability, fast acceleration response and strong power. Its high torque at low speeds and low fuel consumption are superior to those of similar products with the same power. The coefficient of the torque reserve is greater than 35% and the power range covers 286-480PS. The E series complies with the China III and China IV off-road emission standards, which is an ideal power choice for high-end, heavy-duty tractors and other agricultural machinery.

The E series diesel engine was jointly designed by SDEC and AVL (Austria). It is a brand-new 4-valve engine platform made in accordance with the SAIC MOTOR manufacturing standards. Based on the up-to-date engine design concept, the E series engine has an excellent reliability, high efficiency and low fuel consumption that meets the demands of heavy-duty commercial vehicles, construction

| Diesel Engine | Engine Model | Displacement (L) | Aspiration | Rated Power | Peak Torque (N.m) | Solution | Emissions Level | |

| kW | r/min | |||||||

| 10E | SC10E286G3/G4 | 10.4 | TAA | 210 | 2200 | 1300 | CRS+DOC+DPF+SCR | China Ⅲ, China Ⅳ |

| 10E | SC10E300G3/G4 | 10.4 | TAA | 221 | 2200 | 1350 | CRS+DOC+DPF+SCR | China Ⅲ, China Ⅳ |

| 10E | SC10E320G3/G4 | 10.4 | TAA | 235.5 | 2200 | 1500 | CRS+DOC+DPF+SCR | China Ⅲ, China Ⅳ |

| 10E | SC10E340G3/G4 | 10.4 | TAA | 250 | 2200 | 1600 | CRS+DOC+DPF+SCR | China Ⅲ, China Ⅳ |

| 10E | SC10E360G3/G4 | 10.4 | TAA | 265 | 2100 | 1700 | CRS+DOC+DPF+SCR | China Ⅲ, China Ⅳ |

| 10E | SC10E380G3/G4 | 10.4 | TAA | 280 | 2200 | 1900 | CRS+DOC+DPF+SCR | China Ⅲ, China Ⅳ |

| 12E | SC12E380G3/G4 | 11.8 | TAA | 280 | 2000 | 1800 | CRS+DOC+DPF+SCR | China Ⅲ, China Ⅳ |

| 12E | SC12E400G3/G4 | 11.8 | TAA | 295 | 1900 | 1950 | CRS+DOC+DPF+SCR | China Ⅲ, China Ⅳ |

| 12E | SC12E420G3/G4 | 11.8 | TAA | 309 | 2000 | 2000 | CRS+DOC+DPF+SCR | China Ⅲ, China Ⅳ |

| 12E | SC12E430G3/G4 | 11.8 | TAA | 317 | 1900 | 2050 | CRS+DOC+DPF+SCR | China Ⅲ, China Ⅳ |

| 12E | SC12E440G3/G4 | 11.8 | TAA | 324 | 2000 | 2200 | CRS+DOC+DPF+SCR | China Ⅲ, China Ⅳ |

| 12E | SC12E460G3/G4 | 11.8 | TAA | 339 | 1900 | 2200 | CRS+DOC+DPF+SCR | China Ⅲ, China Ⅳ |

| 12E | SC12E480G3/G4 | 11.8 | TAA | 353 | 1900 | 2200 | CRS+DOC+DPF+SCR | China Ⅲ, China Ⅳ |

| Fuel system | The Bosch high pressure common rail system provides multiple injections, a fine fuel atomization, and uniform fuel distribution to facilitate combustion. | It reduces fuel consumption, 10-15% lower than similar products. It meets China III, China IV, and above off-road emission standards. |

| Aspiration method | Based on the design of 4-valve per cylinder and parallel airway, exhaust gas turbochargers are matched properly with working condition. It improves the air intake efficiency. The torque reserve is high, 35% or more. | It features a strong power and excellent response at low engine speeds. |

| Design features | Using the Benz DD13 as prototype engine, SDEC worked with AVL to design the E series with the peak pressure of 190bar. It has the overhead camshaft, Bedplate high strength engine block, and rear gear chamber. During the design stage, noise and vibration reduction is a primary area of concern. With a self-regulated variable-displacement oil pump, integrated oil filter and oil cooler modules, oil is filtered twice for a long oil service life. | It offers durability, user comfort, low noise and vibration. The operating cost is low. |

| Reliability features | The advanced production lines are created by MAG and controlled by an MES system. Based on the quality control system from Volkswagen, engines are produced with consistency and quality. During the research and development stage, the over 20,000h product test for reliability and durability and more than 1,500,000km road test under various working conditions have been completed. | It is a high quality engine with minimal downtime. |

| Matching adaptability | It has optional displacements of 10L, 12L and optional fuel sources of diesel, natural gas. The power range covers 286-480PS. Without an air intake heating device, the engine starts at a cold temperature of -15℃. According to individual working conditions, the matching optimization and customization of powertrain is achieved. The peripheral parts including flywheel, flywheel housing, engine, air compressor, and steering pump are provided with various configurations. Different structures and types are available in PTO and oil pan. | It offers a wide selection of fuel sources and a wide power coverage. The excellent environmental adaptability makes it ideal for different applications. Customization is available to meet any need customers might have. |

| Maintenance | The oil drain interval is up to 80,000km. There is no need to adjust the valve clearances within 80,000-100,000km. The cracked connecting rod offers an easy access to maintenance, with less vulnerable parts. The CAN bus is used for engine control. | It is a durable and reliable engine with low maintenance costs. |

Buy 1 Get 1 Free

Unbetable Quality

Mining, transportation, processing

Construction Assistant

Recent Products

You may add any content here from XStore Control Panel->Sales booster->Request a quote->Ask a question notification

At sem a enim eu vulputate nullam convallis Iaculis vitae odio faucibus adipiscing urna.

Reviews

There are no reviews yet.