TYCOON GROUP(ASIA).,LTD: Development of seawater desalination

Reduce costs

Hydropower cogeneration

Hydropower cogeneration mainly refers to the cogeneration and supply of desalinated water and electricity. Since the cost of desalination depends largely on the cost of electricity and steam, hydropower cogeneration can use the steam and electricity of power plants to power desalination devices, thereby achieving efficient energy utilization and reducing desalination costs. Most foreign desalination plants are built together with power plants, which is the main construction model of large-scale desalination projects.

Thermal membrane cogeneration

Thermal membrane cogeneration mainly adopts a combination of thermal and membrane desalination (i.e. MED-RO or MSF-RO) to meet different water needs and reduce desalination costs. Its advantages are: low investment cost and shared seawater intake. The desalinated product water of RO and MED/MSF devices can be mixed in a certain proportion to meet a variety of needs.

In addition, other combinations of the above methods are also increasingly valued. In actual selection, which method is the best is not absolute, but depends on actual conditions such as scale, energy costs, seawater quality, climate conditions, technology and safety.

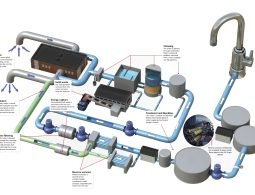

In fact, a large-scale desalination project is often a very complex system engineering. As for the main process, it includes seawater pretreatment, desalination (desalination), desalinated water post-treatment, etc. Pretreatment refers to the necessary treatment of seawater before it enters the desalination device, such as killing marine organisms, reducing turbidity, removing suspended matter (for reverse osmosis), or degassing (for distillation), adding necessary reagents, etc. Desalination is to remove salt from seawater by one of the above methods, which is the core part of the entire desalination system. In addition to requiring efficient desalination, this process often requires solving the corrosion and anti-scaling problems of equipment. Some processes also require corresponding energy recovery measures; post-treatment is the water quality control and storage and transportation of product water from different desalination methods according to different user requirements. No matter which desalination method is used in the seawater desalination process, there are problems such as optimal utilization and recovery of energy, anti-scaling and anti-corrosion of equipment, and correct discharge of concentrated brine. The development and industrial application of seawater desalination technology has a history of half a century. During this period, industrial technologies represented by multi-stage flash evaporation, reverse osmosis and multi-effect evaporation have been formed. Experts generally believe that these three technologies will continue to play a leading role in industrial applications in the next three or four decades, but the proportion of reverse osmosis will increase. From a regional perspective, the Middle East Gulf countries will still choose multi-stage flash evaporation as the first choice because it has the advantages of large-scale and ultra-large-scale (the water output of a single device has reached 40,000 to 50,000 tons of fresh water per day), adaptability to heavily polluted Gulf water, and low pretreatment costs; however, outside the Middle East, reverse osmosis or membrane methods will be the first choice because membrane methods have advantages in energy consumption and cost. Taking North America as an example, development has shown that membrane methods will be the main method in desalination and water treatment.

Development Status

The global daily output of seawater desalination is about 35 million cubic meters, of which 80% is used for drinking water, solving the water supply problem of more than 100 million people, that is, 1/50 of the world’s population relies on seawater desalination for drinking water. There are more than 13,000 seawater desalination plants in the world. As a replacement and incremental technology for freshwater resources, seawater desalination is increasingly valued by many coastal countries in the world; the global direct use of seawater as industrial cooling water is about 600 billion cubic meters per year, replacing a large amount of precious freshwater resources; the world extracts 50 million tons of salt, more than 2.6 million tons of magnesium and magnesium oxide, and 200,000 tons of bromine from the ocean every year. Seawater desalination requires a lot of energy, so the economic benefits are not high in less wealthy countries.

The shortage of freshwater resources in the world has become a growing concern. Some people predict that the 19th century was a fight for coal, the 20th century was a fight for oil, and the 21st century may be a fight for water.

As an open source incremental technology for water resources, seawater desalination has become an important way to solve the global water crisis. By 2006, more than 120 countries and regions in the world had applied seawater desalination technology, and the global daily output of seawater desalination was about 37.75 million tons, of which 80% was used for drinking water, solving the water supply problem of more than 100 million people.

“Getting fresh water from the ocean” has become a thriving industry. By the end of 2006, China’s daily desalination capacity was close to 150,000 tons, doubling from the previous year. China has made major breakthroughs in mainstream seawater desalination key technologies such as reverse osmosis and distillation, and completed a 3,000 cubic meter/day low-temperature multi-effect seawater desalination project with independent intellectual property rights, as well as a 5,000 cubic meter/day reverse osmosis seawater desalination project; seawater direct cooling technology has entered the 10,000 cubic meter/hour level industrial demonstration stage. China’s seawater desalination cost has gradually decreased and is close to 5 yuan/cubic meter.

Although China’s seawater desalination basically has the conditions for industrial development, there is still a large gap between its research level and innovation ability, equipment development and manufacturing capabilities, system design and integration, etc. and foreign countries. The top priority is to form a complete industrial chain for China’s seawater desalination equipment market as soon as possible. Focusing on the key issues that restrict the reduction of seawater desalination costs, we will develop core technologies such as membranes and membrane materials, key equipment, and research and develop new seawater desalination technologies, new processes, new equipment, and new products with independent intellectual property rights, increase the localization rate of key materials and key equipment, and enhance the ability to independently build large-scale seawater desalination projects.

In the next 20 years, the international seawater desalination market will have nearly 70 billion US dollars of business opportunities, and China should occupy a full share. According to the national special plan for seawater utilization, by 2010, China’s seawater desalination scale will reach 800,000 to 1 million tons per day, and by 2020, China’s seawater desalination capacity will reach 2.5 million to 3 million tons per day. In particular, the state actively supports the seawater desalination industry. From January 1, 2008, the income from seawater desalination projects of enterprises will be exempted from income tax. China’s seawater desalination industry has broad development prospects.

Research and Development

A company in Georgia, USA, has developed a new desalination device, which is said to cost only one-third of the existing technology.

According to the latest issue of the British magazine New Scientist, this portable new device can process 11,000 liters of water per day. It uses a technology called “rapid spray evaporation” (RSE): salty water is sprayed into the separation chamber through a pipe to form very fine water droplets; in the hot air of the separation chamber, the water droplets evaporate rapidly, and the water and impurities such as salt are separated; the water vapor is input into the condensation chamber to become pure water, and the salt falls to the bottom of the separation chamber. In traditional technology, the salt is recovered and gathered on the pipe, which is difficult to remove.

The company said that the new technology is much more efficient than existing technologies such as reverse osmosis. Tests have shown that it can process water with a salt content of up to 16%, which is much higher than the concentration of ordinary seawater. On average, it costs 16 to 27 cents to produce 1,000 liters of fresh water. Scientists say that this device can also treat wastewater. The recovery efficiency of RSE technology can reach 95%, while traditional technology can only reach 35%. The investment is only one-fourth of that of distillation and reverse osmosis, and the operation and maintenance costs are greatly reduced.

“I try as much as possible to give you a great basic product and what comes out, I feel, is really amazing.”

Kathryn Murphy

Founder

Desalination development in China

Development History

China’s seawater desalination technology has developed under the support of the government and driven by national key research projects. The research and development of seawater desalination technologies such as electrodialysis, reverse osmosis and distillation (multi-stage flash evaporation, compressed gas distillation and low-temperature multi-effect distillation) have made considerable progress. In 1958, the first research on electrodialysis seawater desalination was carried out. From 1967 to 1969, the State Science and Technology Commission and the State Oceanic Administration jointly organized a national seawater desalination campaign. The main force of the exhibition established the first seawater desalination laboratory in China in Hangzhou (the seawater desalination laboratory of the Second Institute of Oceanography of the State Oceanic Administration, the predecessor of the Hangzhou Water Treatment Technology Research and Development Center of the State Oceanic Administration). At the same time, the research on various seawater desalination technologies such as electrodialysis, reverse osmosis and distillation was carried out, laying the foundation for the development of seawater desalination.

In 1965, the Department of Chemistry of Shandong Ocean University was the first in China to conduct research on reverse osmosis CA asymmetric membranes; in the 1970s, hollow fiber and spiral RO membranes and components were studied and initially industrialized. Since the Seventh Five-Year Plan, the development and research of reverse osmosis desalination technology has been included in the national key research projects. During the Seventh Five-Year Plan, the development of medium and low salinity reverse osmosis membranes and components was completed, and a seawater desalination demonstration project was established; during the Eighth Five-Year Plan, great progress was made in the development of medium salinity reverse osmosis membranes; the Ninth Five-Year Plan made the pilot scale-up of the new polyamide composite membrane successful, combined with the introduction of key technologies and equipment, and now polyamide composite membrane products are produced.

In 1997, the Hangzhou Water Treatment Technology Research and Development Center of the State Oceanic Administration, with the support of Zhejiang Province’s major science and technology special funds, built a 500 cubic meters/day reverse osmosis desalination demonstration project in Shengshan Town, Zhoushan City, Zhejiang Province. The power consumption per ton of water is less than 5.5 degrees, and the technical and economic indicators are at the world’s advanced level with the same capacity.

In 2000, with the support of the major scientific and technological research plan of the Ministry of Science and Technology, Hangzhou Water Treatment Center built a 1,000-ton/day reverse osmosis desalination demonstration project in Changdao, Shandong and Shengsi, Zhejiang. It was the first to apply the internationally advanced power exchange energy recovery device, and the water production energy consumption dropped to 4 degrees/ton, reaching the international advanced level. The completion of this demonstration project laid the foundation for the rapid development of my country’s reverse osmosis desalination technology. In 2001, it won the second prize of the State Oceanic Administration’s marine innovation achievement. In 2002, the center built a 10,000-ton reverse osmosis desalination demonstration project in Rongcheng, Shandong with the support of the National Development and Reform Commission’s industrialization project. Through optimized design and a significant reduction in equipment investment, the economic efficiency of the project was further improved, forming a proprietary technology with my country’s independent intellectual property rights, achieving significant economic and social benefits, and promoting the rapid development of my country’s membrane separation technology and especially the reverse osmosis desalination industry. Thus, an effective technical approach has been created for the water use of coastal enterprises and institutions and the domestic water use of residents. In 2004, the project was awarded the first prize of the first “China Membrane Industry Association Science and Technology Award” by the China Membrane Industry Association.

my country has built a desalination scale of 800,000 tons/day, mainly based on reverse osmosis. The largest reverse osmosis desalination project built is the 50,000m3/d desalination project in Caofeidian, Hebei, undertaken by Hangzhou Water Treatment Center. In addition, research on NF-RO integrated desalination has been carried out. The 100,000 tons/day desalination project of Zhejiang Liuheng Water has completed the first phase of construction. After completion, it will become the largest desalination project of its kind in China.

In the 1960s, the Shanghai 704 Institute of the former Ministry of Shipbuilding Industry developed a 5 m3/d compressed steam distillation desalination device and a flash desalination device using the waste heat of diesel engine cylinder jacket water to equip ships for use. In the 1970s and early 1980s, the Tianjin Science and Technology Commission supported a multi-stage flash evaporation pilot study with a daily output of 100 tons of fresh water, and obtained certain design parameters and experience. After the 1980s, the Tianjin Institute of Seawater Desalination and Comprehensive Utilization of the State Oceanic Administration carried out the development of a 30 m3/d scale compressed steam distillation unit, including a 30 m3/d vertical tube atmospheric pressure compressed steam distillation unit and a 30 m3/d horizontal tube negative pressure compressed steam distillation unit (operating temperature 72°C) and a 30 m3/dOTE/VC desalination unit. The achievements and problems encountered in the above research work have accumulated rich experience for later research and played an important role in promoting the development of distillation desalination technology in my country.

In June 2004, the 3000 m3/d low-temperature multi-effect distillation desalination project designed by the Tianjin Institute of Seawater Desalination and Comprehensive Utilization of the State Oceanic Administration was successfully tested in Shandong Huangdao Power Plant and passed the operation test for more than 9 months. The desalination unit is the first multi-effect distillation desalination unit with completely independent intellectual property rights in China, and the localization rate of the unit is 99%. The completion of the construction of the desalination unit shows that my country has initially mastered the complete set of technology for large-scale low-temperature multi-effect distillation desalination. In addition, the design of the 10,000 m3/d multi-effect distillation demonstration project has been completed and construction will begin.

In September 2023, the Marine Strategic Planning and Economic Department of the Ministry of Natural Resources released the “2022 National Seawater Utilization Report”, which showed that 2022 was the year with the largest scale of new seawater desalination projects in my country so far. There are 150 seawater desalination projects in the country with a project scale of 2,357,048 tons/day, an increase of 500,615 tons/day compared with 2021. The national seawater desalination projects are distributed in 10 coastal provinces (autonomous regions) and municipalities, including Liaoning, Tianjin, Hebei, Shandong, Jiangsu, Zhejiang, Fujian, Guangdong, Guangxi and Hainan. The main uses of desalinated water are industrial water and domestic water. [9]

On March 21, 2024, according to the Ministry of Natural Resources, in 2023, the national marine gross domestic product will be 9,909.7 billion yuan. From the internal structure, the total volume of seawater desalination and comprehensive utilization industry will be 32.7 billion yuan, with a growth rate of 4.5%. [10]

Main tasks

The 12th Five-Year Plan for the Development of Seawater Desalination Industry proposes five main tasks. First, strengthen technological innovation, rely on technological progress, enhance innovation capabilities, accelerate the pace of research and development of core technologies and key components for seawater desalination, and improve the core competitiveness of seawater desalination as soon as possible; second, strengthen equipment manufacturing, increase design, research and development and manufacturing efforts, optimize the design and manufacturing technology of seawater desalination units and complete sets of equipment, and improve the manufacturing capabilities of key equipment and complete sets of equipment; third, focus on engineering demonstration, improve process design level and engineering construction capabilities, rely on key projects, and promote the industrialization demonstration of core and key technologies for seawater desalination; fourth, accelerate the application of desalinated water, expand the scale of seawater desalination water application, improve the utilization efficiency and benefits of seawater desalination water, and give full play to the guarantee role of seawater desalination water; fifth, establish standards and specifications to promote the healthy development of the seawater desalination industry.

Key tasks

In order to successfully complete the main tasks determined in the Plan, our Commission will focus on the following tasks: First, strengthen the research and development of key technologies and equipment, improve the research and development capabilities and technical integration level of key equipment and complete sets of equipment for seawater desalination; second, improve the level of engineering technology, actively research and develop engineering technology and complete sets of equipment for all aspects of seawater desalination; third, cultivate a seawater desalination industrial base, and create a group of seawater desalination equipment manufacturing companies and engineering design and construction companies with international competitiveness; fourth, establish a seawater desalination industry alliance, so that various types of scattered resources and capabilities can form a joint force to participate in market competition and form a complete industrial chain; fifth, implement seawater desalination demonstration projects, which can not only produce qualified desalinated water, but also provide a good industrial demonstration platform; sixth, build seawater desalination demonstration cities (islands, industrial parks) to promote industrial development; seventh, promote the use of seawater desalination water, and enhance its role in supplementing and guaranteeing water resources; eighth, establish and improve the standard system to guide the healthy and rapid development of the seawater desalination industry.

Guarantee measures

The Plan proposes 9 guarantee measures. First, improve the level of awareness and accurately grasp the strategic positioning of seawater desalination as an important supplement and strategic reserve of water resources. Second, improve laws and regulations, guide and regulate the development of seawater desalination industry from the aspects of resource development, environmental protection, safe supply and industrial development. Third, establish a support system to ensure the healthy and rapid development of seawater desalination industry. Fourth, strengthen policy guidance. Fifth, strengthen supervision and management. Sixth, form an industrial alliance to improve market competitiveness through cooperation. Seventh, actively promote application and improve the overall level of development of my country’s seawater desalination industry. Eighth, strengthen exchanges and training. Ninth, strengthen organization and coordination, establish an inter-ministerial coordination mechanism for the development of seawater desalination industry led by the National Development and Reform Commission, and participated by relevant departments such as the Ministry of Science and Technology, the Ministry of Industry and Information Technology, the Ministry of Finance, the Ministry of Environmental Protection, the Ministry of Housing and Urban-Rural Development, the Ministry of Water Resources, the Ministry of Health, the State Administration of Taxation, the General Administration of Quality Supervision, Inspection and Quarantine, the Energy Bureau, and the State Oceanic Administration to jointly promote industrial development.